Scenario 1: the pick-up drums do not roll, you hear a grinding noise

You most likely hear a grinding noise of plastic cogwheels slipping when the printer tries to feed a sheet of paper.

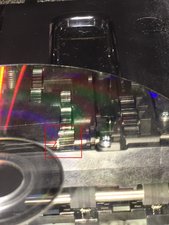

It looks like there is too much play in the paper pick-up unit (at the rightmost end inside the printer) on which both pick-up drums are mounted on a single arm. When not printing, these drums are lifted. When printing, they are dropped to the top of the paper stack and will engage to separate the topmost sheet off the stack.

When lifted, you will be able to rotate these drums in one direction. When the drums touch the paper, they simply don't rotate.

I suppose that because of excess play (programmed obsolescence?) eventually the cogwheels that drive the drums will slip. Sadly this unit is hard to reach.

Probably the entire printer must be torn down, and I don't expect you will be able to easily fix the excess play on the paper pick-up mechanism that drive the rubber rolls when pressed on the stack of paper.

Scenario 2: the pick-up drums do roll, but they slip on the paper

There are image and video instructions available from HP. Here's a written summary based on my experience:

If you see the paper pick-up drums slip on the paper, then you may have better luck. Unplug the printer's power cord, detach the duplex unit at the back (push to the left and pull back to disengage the unit from the printer). You can now see 4 rubber drums on an axis. Clean these with a Q-tip moistened (not soaked) in clean water, and move from left to right. Rotate the axis upward (only possible way) to clean the next section of the 4 rubber drums. Now take another moist Q-tip and swipe the rubber-covered grooved paper pick-up drums clean in a similar fashion. This is tricky since you need to reach into the printer from the back (left). Let the water evaporate and reassemble the duplex unit. Print a test page (e.g., a blank Word document to avoid wasting ink). If the rubber pick-up drums still slip, repeat the cleansing operation.

2

2  2

2  1

1

댓글 36개

I did the same thing and fixed my prroblem - thanks much!

Frank Bryan 의

It worked !! Thanks a million... we also cut out a hole under the carriage...

lbennett1669 의

Perfect! My printer has been broken for 6 months! I was going to buy a new printer, then I found your post. It worked` thank you so much!!

Tina 의

I cut a hole in the bottom and it was very easy to see the problem and access!

I used super glue and it was dry and ready to go in an hour.

Tina 의

I cut a hole in the bottom and it was very easy to see the problem and access!

I used super glue and it was dry and ready to go in an hour.

Tina 의

댓글 31개 더보기