Can't remove tri point 000 screws in iPhone with ifixit bit.

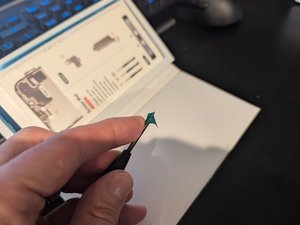

I'm having a difficult time removing the y000 screws in the iphone 7. I got this bit from ifixit. I don't feel like this bit is truly getting a good grip in the screw. I've stripped 2 of them on the home button. I need to remove the lcd plate and home buttom for a screen replacement. Are these bits not high quality bits? I've seen in other forums where they say it's crucial to have a quality bit or they'll strip easily. I managed to get one off but the others won't budge. I've had not issues with the phillips screws and easily got the camera off. Now I'm going to have to take this to a repair shop and ask them to remove these screws for me. I've tried using a rubber band and duct tape with no luck. Anyone have suggestions on a higher quality bit? I only have the y000 and y0 bits. Not the y00 so can't try the next largest bit.

좋은 질문입니까?

2

2  3

3  1

1

댓글 2개

what where you going do with the ruberband and duct tape is some method to getting a the srew out?

Kamal Fambare 의

Yes, a good tip to removing a screw with a stripped head, is to put a rubber band (single layer, not double), over the screw head, then try again. The thickness of the elastic, plus the extra grip it gets, will most times allow you to get the screw out. I guess the same MAY work with Duct tape, but I have never had to try. Rubber bands usually work for me, (& I only have to follow the postman a few yards up the road, where he discards them!).

I would normally use a replacement screw, rather than trying to get the damaged one back in, just in case I have to remove it again!

Gary Hooper 의